Modern consumer electronics — with vibrant displays, high resolutions, and high-fidelity audio — not only provide a wide array of sensory feedback, but also have an enviable flexibility thanks to the ubiquitous touchscreen.

Free from physical keyboards, designers have used the touchscreen to create versatile inputs for any software you can imagine, from sports betting to the group chat. But all of this has, ironically, left one sense behind: we’re out of touch.

Now, researchers in Carnegie Mellon’s Future Interfaces Group are looking to bring back true tactile feedback by manipulating liquid inside touchscreens to create, essentially, buttons-on-demand.

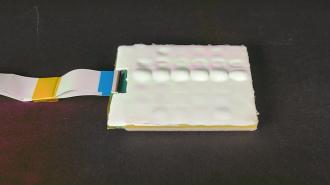

Researches are manipulating tiny pumps and a liquid medium to create physic touchscreen buttons on demand.

“Audio and video feedback are so ingrained in our everyday lives that we hardly give these technologies a second thought,” researchers Craig Schultz and Chris Harrison, of CMU’s Human-Computer Interaction Institute, wrote in their paper on the technology.

“Haptic [touch-related] devices, on the other hand, have failed to reach this same level of capability and pervasiveness.”

At your fingertips: There’s still some tactile feedback in the classic sense on devices — think the continued presence of physical buttons like the volume controls on your smartphone.

But when buttons, switches, etc. are stripped away, devices make due with other measures, mainly vibrations, to indicate interaction. Although these are useful, the researchers wrote, they can’t match physical objects; there’s a reason even touchscreen-based laptops still have mechanical keyboards, as Gizmodo points out.

“To put it simply, there is a wide gulf between the types of things we can feel and the ability of our devices to render these same types of feelings,” the researchers wrote.

Schultz and Harrison’s solution, which they call Flat Panel Haptics, wants to provide tactile feedback on our devices the same way the world beyond the screen does: through the presence of physical buttons.

The key to Flat Panel Haptics is a thin layer of electroosmotic pumps (EEOPs). These pumps use electricity, not mechanical means, to move liquid, and have been engineered to 1.5 millimeters thick. When stacked with a layer of liquid, the EEOPs can create buttons which can protrude roughly 5 millimeters and have the tensile strength to be pressed.

Flat Panel Haptics were inspired by LCD displays. LCDs use a thin layer and electrical voltage to manipulate pixels and create an image; crucially, the tech can “be built in many form factors and at low cost,” and consequently, we have high-res images all around us now.

“With a similar end in mind for flat panel haptic displays, we focused on materials and methods that are inexpensive, simple, scalable, and bootstrap existing supply chains and materials,” the researchers wrote. “All materials were easily procured, processed, and assembled in our lab.”

Thin margins: The Carnegie Mellon team isn’t the first to try and improve tactile feedback for touchscreen devices; a company called Tactus already brought similar tech to the market in 2015.

Tactus’ device, called the Phorm, took the, ahem, form of a case for iPad Mini. At the flip of a switch, buttons would rise from the layer of liquid inside the Phorm, disappearing again when switched off. Reviewers at Engadget found the Phorm to fall short of a keypad, however; typing was awkward, and was a bit bulky.

When dealing with touchscreen devices that have become progressively slim, that heft is a concern. The CMU device was designed with this in mind, designed to be within 5 millimeters thick, all-in, with the EEOP, liquid, and OLED screen layers.

As is, Flat Panel Haptics still has limitations, Gizmodo notes, which may harm its adoption, namely that the button shape and size is currently predetermined. To extend the LCD metaphor, however, if the EEOPs are engineered to be close to the size of pixels, buttons of different sizes and shapes could be generated on demand.

There’s also some extra safety concerns to work out, the researchers wrote. EEOPs require a “moderately high voltage” and a solvent for the pumping fluid, leading to some risk for shock and chemical exposure — namely skin irritation with prolonged exposure.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at tips@freethink.com.