This article is an installment of Future Explored, a weekly guide to world-changing technology. You can get stories like this one straight to your inbox every Thursday morning by subscribing here.

Silicon Valley startup Sakuu has developed a 3D-printing platform that it says can mass produce solid-state batteries, in any shape and size — finally allowing us to take advantage of the tech’s many benefits.

“We believe we have the only known solution for manufacturing solid-state batteries at scale with our novel Kavian platform,” said Robert Bagheri, Sakuu’s founder and CEO.

Solid-state batteries: Most of today’s battery-powered devices rely on lithium-ion batteries, which degrade quickly, take a long time to charge, and can sometimes catch fire. This makes them less-than-ideal for electric vehicles (EVs), renewable energy storage, and other uses to combat climate change.

Solid-state batteries could challenge lithium-ion’s dominance.

“Solid-state batteries, I think, are one of the most important topics that I’m super excited by.”

Venkat Srinivasan

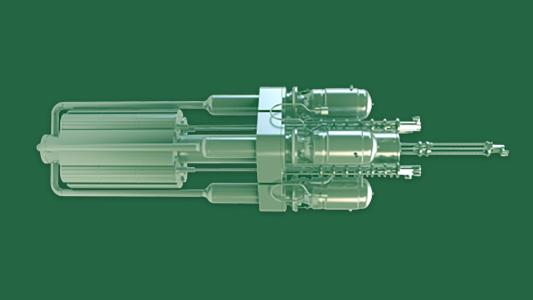

They have the same basic parts: a positively charged cathode, a negatively charged anode, a separator between the two, and an electrolyte that carries the current from the cathode to the anode (and vice versa when the battery is charging).

The difference in a solid-state battery is the electrolyte: rather than being a liquid or gel, it’s a solid material.

Why it matters: Solid-state batteries have many advantages over their lithium-ion counterparts — they don’t degrade as quickly, have shorter charge times, and are less of a safety hazard.

They also have a greater energy density, meaning they could store more energy or cut down on the size of our batteries. This could be huge for electric vehicles, where battery size and weight is a major issue — heavy batteries are a big drag on range.

“Solid-state batteries, I think, are one of the most important topics that I’m super excited by,” Venkat Srinivasan, director of the Argonne National Laboratory’s Collaborative Center for Energy Storage Science, told Freethink’s Hard Reset.

The challenge: A number of startups have now demonstrated the benefits of solid-state batteries in the lab, and we’ve even seen these batteries deployed in pacemakers, smart watches, and other small devices.

If we want to start using solid-state batteries in smartphones, EVs, and more, though, we need to be able to mass produce them — and no one has figured out a commercially viable way to scale-up their production yet.

“We believe we have the only known solution for manufacturing solid-state batteries at scale.”

Robert Bagheri

A major reason for this is that the method often used to mass produce lithium-ion batteries — layering the battery components on top of a flexible substrate — isn’t ideal for combining the parts of a solid-state battery.

“If you try to build that up using sheets of individual materials, it’s very difficult to get interfaces that work correctly, especially at the scale you need, typically 20 to 30 microns thick,” Dave Pederson, Sakuu’s VP of marketing and business development, told Additive Manufacturing.

“They’re very difficult to handle, and it’s very difficult to make sure they touch adequately without the use of liquids,” he continued.

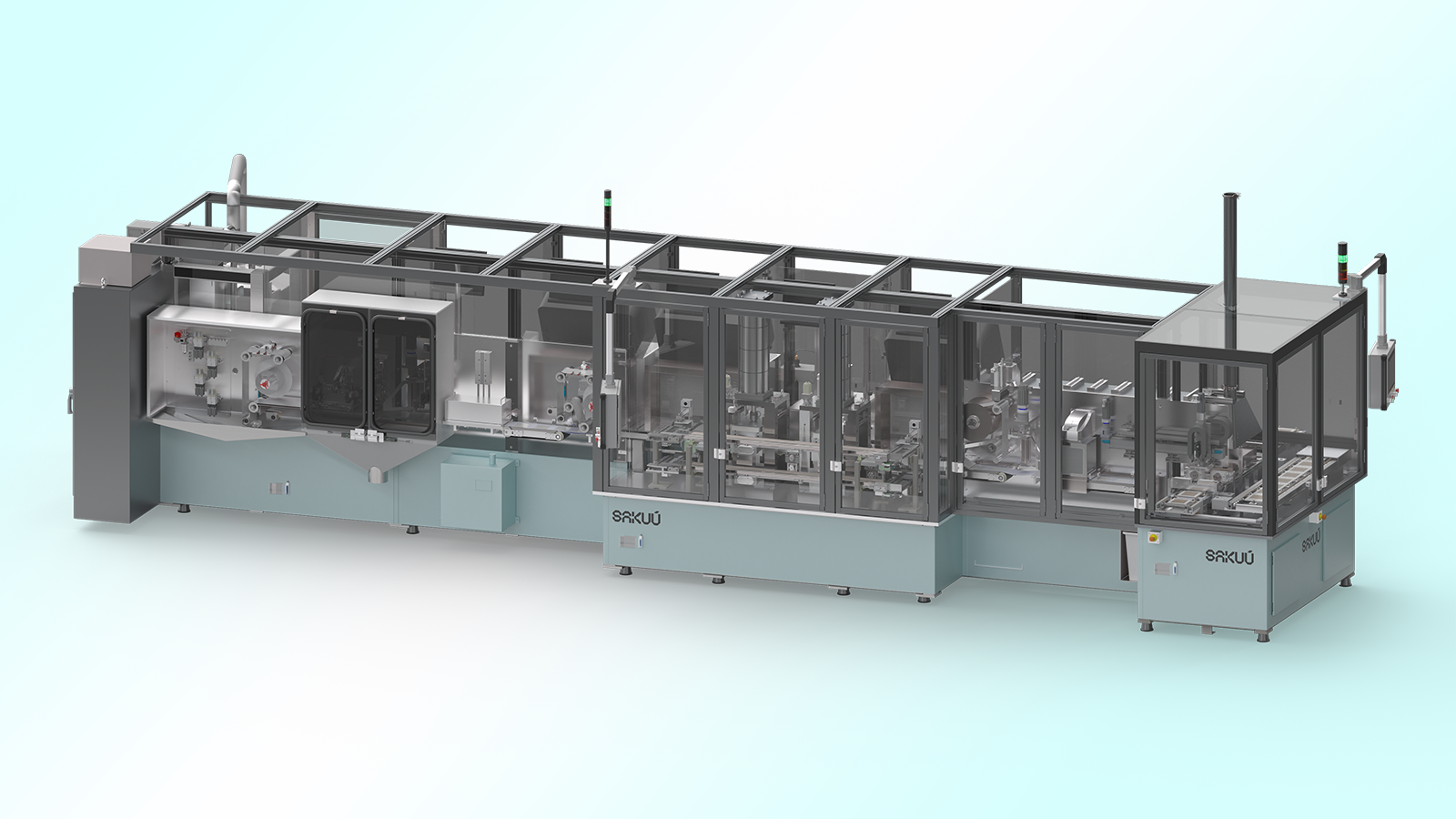

What’s new? Instead of stacking individual battery components in layers, Sakuu’s Kavian platform uses 3D printing to assemble the materials needed for lithium-ion, lithium-metal, or solid-state designs in one layer, a process the company calls “SwiftPrint.”

“The Kavian platform can print ceramic, glass, metals, and polymer — in the same layer,” Arwed Niestroj, Sakuu’s SVP of customer enablement, told TCT Magazine.

“Conventional additive manufacturing processes perform each 3D-printing step in series, whereas Kavian performs all steps in parallel, enabling a streamlined model that saves energy, cost, labour, materials, and time, while also increasing quality and reliability,” he added.

Compared to leading lithium-ion batteries, Sakuu says its solid-state batteries are 50% smaller and 40% lighter. The Kavian platform itself, meanwhile, is 44% smaller than the equipment traditionally used to manufacture lithium-ion batteries.

“The Kavian platform can enable commercial-scale, sustainable production of … solid-state batteries.”

Karl Littau

Sakuu says SwiftPrint not only allows for the creation of solid-state batteries at scale, but also gives manufacturers the option of producing batteries in custom shapes and sizes — instead of designing devices to accommodate batteries, they could design batteries that fit their devices.

Sakuu revealed its first 3D-printed solid-state battery in 2021, and it’s now announced that it has been able to “successfully and consistently” print those batteries — as well as lithium-ion and lithium-metal designs — in a variety of shapes at the pilot line facility it opened in 2022.

“Our development shows that the Kavian platform can enable commercial-scale, sustainable production of a wide range of battery technologies from lithium-ion to lithium metal to even solid-state batteries — whereas traditional methods of advanced cell manufacturing continually run into core impediments that prevent mass-scale production,” said CTO Karl Littau.

Looking ahead: Sakuu anticipates selling its Kavian platform directly to a variety of customers, including battery manufacturers, automakers, aerospace developers, and renewable energy companies.

In January 2023, the company announced that it had hired Porsche Consulting, a subsidiary of the Porsche automaker, to design “gigafactories” for commercial manufacturing. The first facility will produce lithium-metal batteries, with solid-state batteries planned for subsequent builds.

Sakuu’s goal is to open gigafactories with partners around the globe, and by 2030, it hopes to be manufacturing 200 GWh of battery capacity annually. To put that into context, China — where 77% of the world’s lithium-ion batteries are made — outputs almost 900 GWh annually.

It’s too soon to predict whether Sakuu will reach that goal, but if it can effectively scale up its tech, we could start seeing a range of electronic devices — including EVs — with better capacities and fewer safety concerns thanks to its 3D-printed solid-state batteries.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].