An advanced bionic arm can be life-changing for a person with an upper limb amputation. But in India, with a population of nearly 1.4 billion and average income of just $2,000 a year, advanced prosthetics are financially out of reach for many amputees.

So the Indian startup Makers Hive developed one that’s not only 90% cheaper, but also more functional.

Advanced prosthetics: A bionic arm contains sensors that press against the skin of the wearer’s residual limb to detect electrical signals from their nerves.

When a wearer thinks about pointing at something with their missing hand, the muscles in their residual limb will still produce signals that are distinct from the signals produced when they think about pinching two fingers together.

The bionic arm learns to differentiate between all these hand grip signals and translates the wearer’s intended movement into a command for their prosthetic hand — they think about pointing, and the hand points.

The challenge: The average bionic arm can support 14 different grips, and that variety can dramatically increase an amputee’s independence and improve their quality of life.

“Unlike a leg, the functioning of an arm is very complex,” Pranav Vempati, founder of Makers Hive, told the Times of India in 2020. “For instance, if you want to tie a shoe lace, the grip required is very different from that of the grip one needs to hold a bottle.”

However, a bionic arm with all of those grip options doesn’t come cheap.

“These advanced prosthetic bionic hands cost as much as (approximately $47,000 to $80,000) in developed nations,” Vempati told the Better India. “In countries like India, most households cannot afford them.”

We wanted to build a product which is future-proof.

Pranav Vempati

The KalArm: Vempati researched the prosthetic arms people in India were buying and discovered that $2,500 devices with just one function were the norm, so in 2018, he founded Makers Hive to create an advanced bionic arm close to that price point.

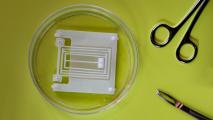

The 3D-printed, lightweight KalArm is the result of those efforts. It features 16 grips, customizable panels, and a companion app, which can be used to monitor the arm’s performance, as well as install firmware updates.

“The hand works standalone without the app, but we wanted to build a product which is future-proof,” Pranav said.

To keep costs from ballooning, Makers Hive built and tested many of its components in-house. The result is a bionic arm that costs approximately $4,700 to $5,400 — making it 90% cheaper than comparable devices.

Looking ahead: Early testers have raved about the KalArm, and the company expects to begin filling its hundreds of preorders around September.

Makers Hive is also in talks with government organizations about getting the cost subsidized for those who still can’t afford the bionic arm, ensuring everyone has equal access to the potentially life-changing prosthetic.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].