If something breaks in space, repairing it can be a matter of life and death. But flying tools and spare parts into space is pricey: Anywhere from $4,500 per kilogram to $60,000 per kilogram, depending on the type of cargo and destination. Something like this toolbox–actually made for use on the International Space Station–costs a fortune to get off planet Earth.

“No matter how much rockets bring down cost, this doesn’t fix the problem of the things that can’t be launched–the un-launchables. We want to make the un-launchables.” – Jason Dunn, co-founder of Made In Space

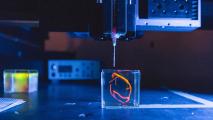

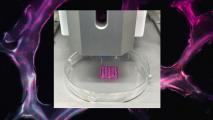

But there’s now a new way for astronauts to get some of the tools they need: They can simply tell a robot to build tools they need, as they need them, using a light-yet-durable material. Astronauts aboard the International Space Station are doing this right now using two zero-gravity 3D printers from a startup called Made In Space.

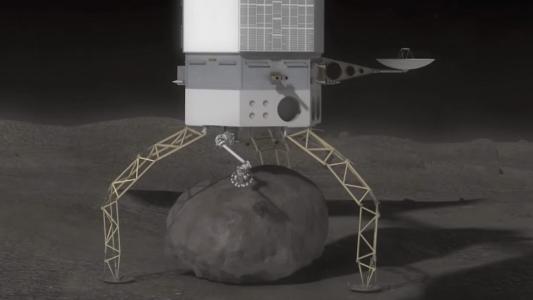

Started by a group of 30-something aerospace nerds, the company’s printer made history by allowing humans to manufacture off-planet for the first time in the history of mankind. Not bad for a startup. And it could be just the beginning; Within a decade, Made In Space hopes to manufacture things in space that are so large humans couldn’t launch them if we wanted to. Like asteroid ships.