The same process used to make beer is now being applied to brew cooking oil — and the result is healthier and more sustainable than the vegetable oils we use today.

The challenge: Just 100 years ago, vegetable oils were practically nonexistent in the human diet. Today, they’re a major part of it: 740 million acres — an area that would cover 90% of India — are dedicated to growing soybeans, palm trees, and other oilseed crops.

While these cooking oils can make food extra tasty, oilseed crop production releases greenhouse gasses, contributes to biodiversity loss, and consumes freshwater that could otherwise be used for drinking or to grow other food.

“[Cultured Oil has] a fraction of the environmental footprint.”

Jeff Nobbs

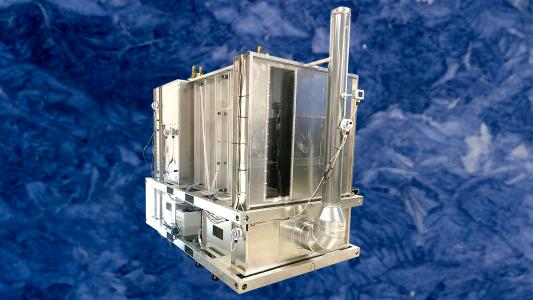

Cultured oil: Instead of dedicating land and other farming resources to oilseed crops, alt-food startup Zero Acre Farms wants us to start using a cultured oil it produces through fermentation.

Fermentation is a metabolic process in which microorganisms, such as yeasts, molds, and bacteria, break down carbohydrates. Depending on the microbe and the carb, this can produce ethanol, lactic acid, milk proteins, and more.

Zero Acre’s oil starts with a culture of food-producing microorganisms (the company doesn’t specify which kinds). Natural plant sugars sourced from sugarcane and sugar beets are then added to the culture, and the microorganisms convert them into oils and fats.

Why it matters: According to Zero Acre, its cultured oil is healthier and more sustainable than traditional kinds. Even with the cane and beet sugar, it uses 85% less land than canola oil, emits 86% less carbon dioxide than soybean oil, and requires 99% less water than olive oil.

“Fermentation is the original culinary art, after fire,” said CEO Jeff Nobbs. “We use this ancient technique to produce oils and fats with significantly lower levels of the bad fats that have been linked to inflammation and disease while having a fraction of the environmental footprint.”

The bottom line: Zero Acre’s cultured oil has a high smoke point (485 F) and a neutral flavor, making it a versatile ingredient. It’s also very expensive: $30 per 16-ounce bottle. However, if there’s enough demand, the startup hopes to be able to scale up manufacturing and lower costs.

Even if the cultured oil is never cheap enough for restaurants to use in industrial fryers, Zero Acre says replacing just 5% of the oils used in the US today with this more sustainable alternative would free up 3.1 million acres of land every year — an area about the size of Connecticut.

Update, 8/17/22, 5:30 p.m. ET: This article was updated to clarify that the oil is not created in a lab.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].