Using a new 3D-printing technique, Japanese researchers have created a morsel of lab-grown beef with the distinct marbling of fat found in Wagyu steaks — and it could one day let you design your perfect cut of beef.

The challenge: Demand for meat has never been higher, but the way we traditionally get it — by raising and slaughtering livestock — is both bad for the environment and arguably unethical.

That’s led to an increased interest in meat alternatives, including cultured meat. This meat is grown from stem cells in a lab, and because it’s molecularly identical to the “real” stuff, it can perfectly replicate its flavor.

It’s texture? Not so much.

“[Our method] can produce tailor-made complex structures, like muscle fibers, fat, and blood vessels.”

Dong-Hee Kang

Right now, most lab-grown beef is akin to the ground stuff you’d use to make burgers, but researchers want to replicate steak, too. This is more challenging as they need to figure out how to match meat’s distinct layers of muscle and fat.

Printing lab-grown beef: Now, Osaka University scientists appear on track to overcome this issue, demonstrating how 3D printers can be used to create a (small) cut of Wagyu beef, which is famous for its distinct marbling of fat.

“Using the histological structure of Wagyu beef as a blueprint, we have developed a 3D-printing method that can produce tailor-made complex structures, like muscle fibers, fat, and blood vessels,” lead author Dong-Hee Kang said in a press release.

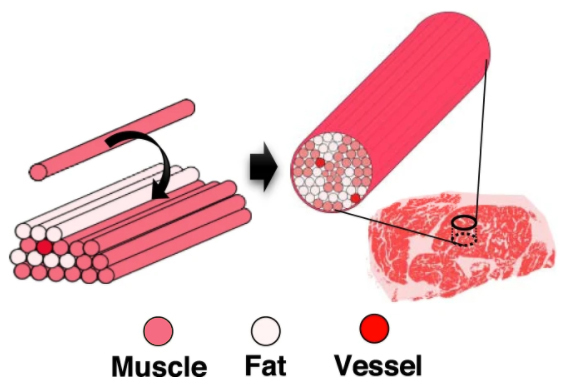

The marbling process: The researchers started by coaxing two types of stem cells to grow into the different types of cells found in a steak. They then used their 3D-printing technique to create muscle, fat, and blood vessel fibers from those cells.

After stacking those fibers together in a precise pattern, they cut across them to create their “steak” — imagine glueing a bunch of dry spaghetti noodles tightly together and then slicing the long cylinder into little patties.

Design your steak: So far, the researchers have only produced a very small piece of lab-grown beef, and it’s not clear what it would take to scale-up the process or make it cost effective.

Still, it’s a start, and the researchers believe the technique might one day even lead to personalized cuts of lab-grown beef that have the exact ratio of muscle-to-fat that a diner prefers.

“By improving this technology, it will be possible to not only reproduce complex meat structures, such as the beautiful sashi of Wagyu beef, but to also make subtle adjustments to the fat and muscle components,” senior author Michiya Matsusaki said.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].